Welcome to MICRESS®

The Microstructure Evolution Simulation Software

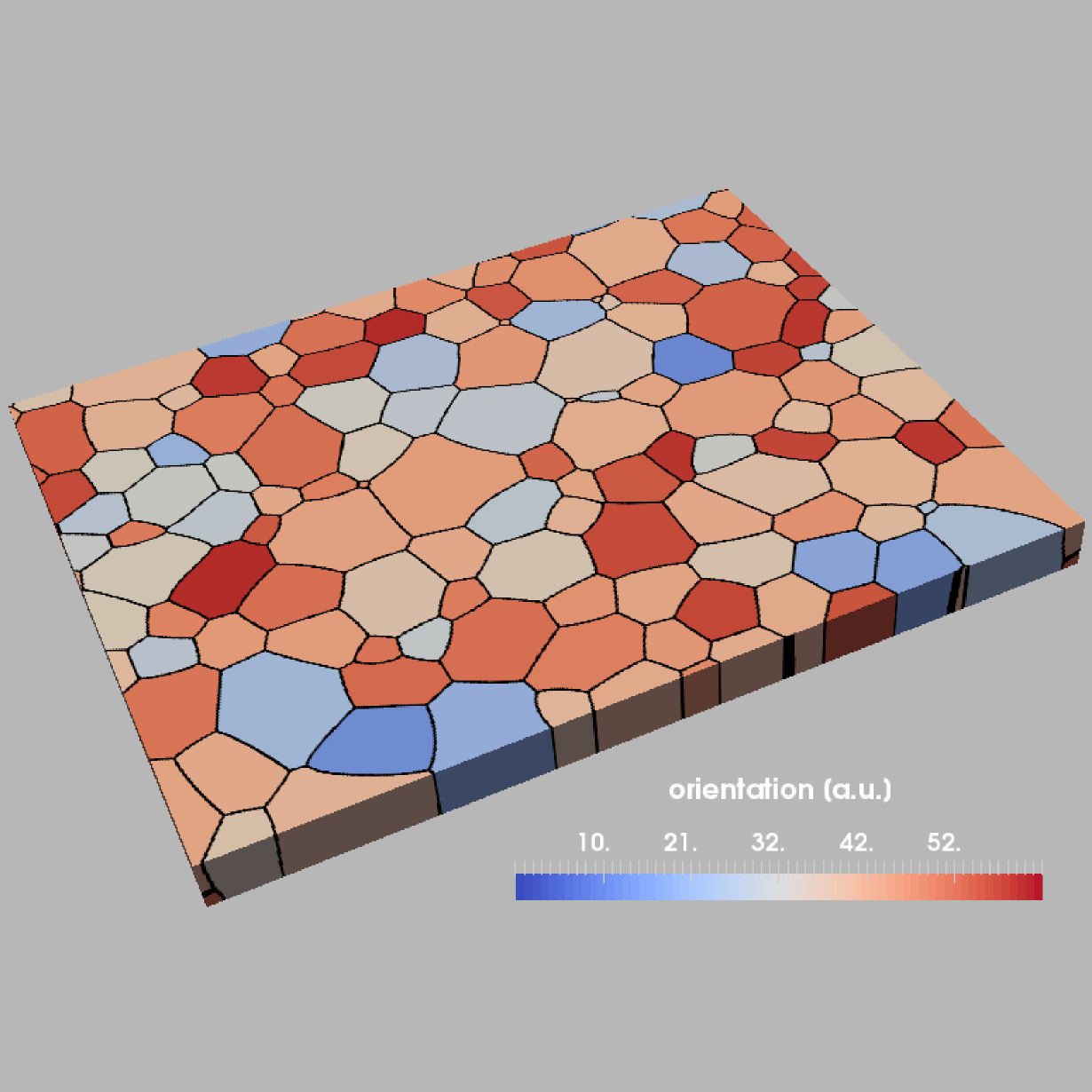

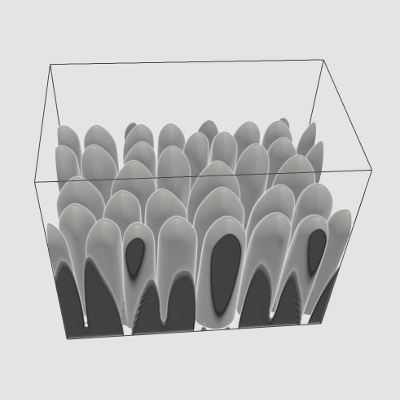

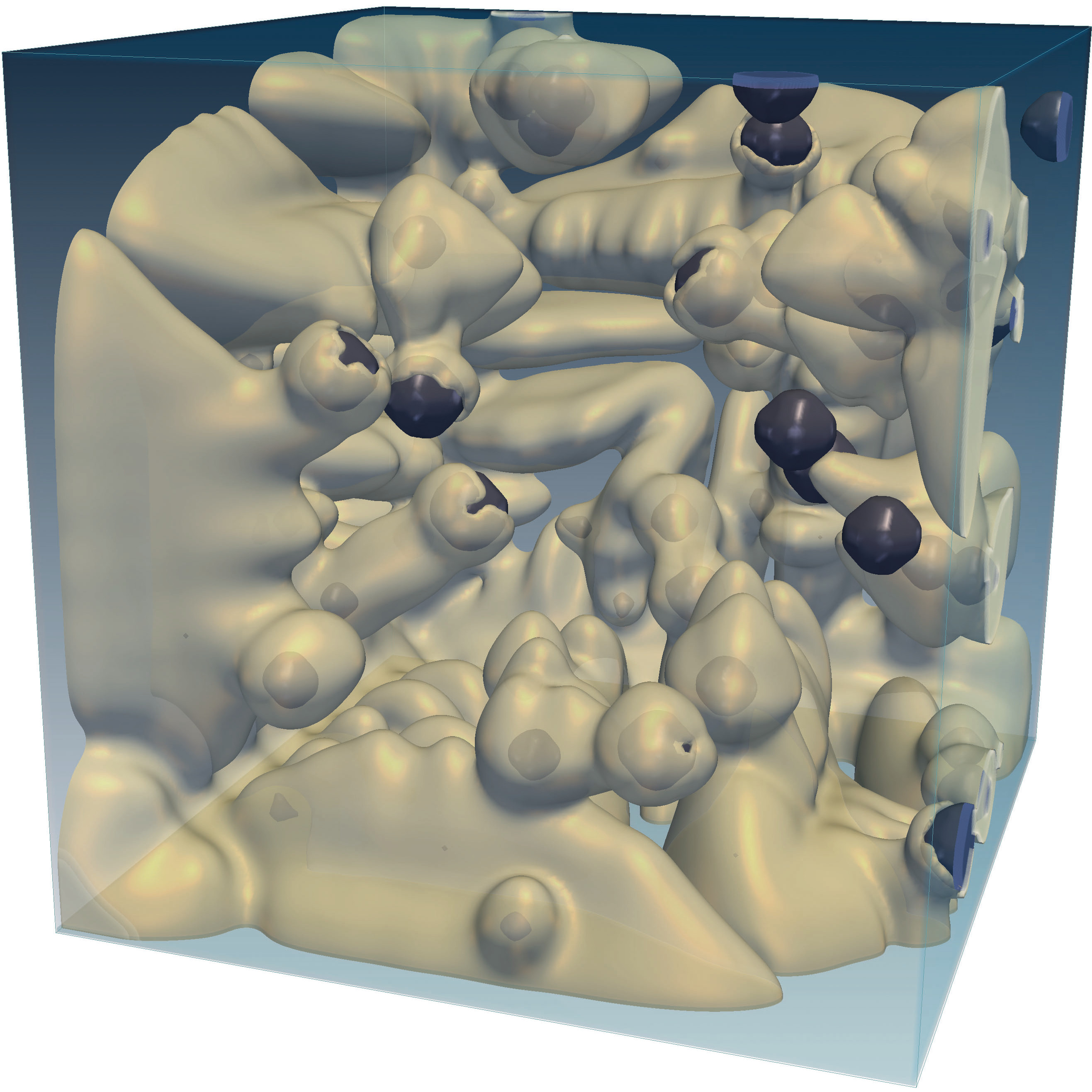

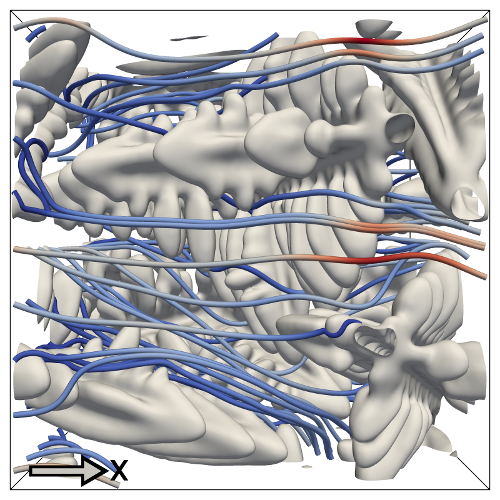

The properties of almost any material are largely determined by its structure and especially by its microstructure. MICRESS®- the MICRostructure Evolution Simulation Software - is a software enabling the calculation of microstructure formation in time and space during phase transformations, especially in metallurgical systems. The software is based on the multiphase-field concept, which has been developed by ACCESS scientists since 1995. Read more...